The term motor cable reel refers to a specialized cable management device that is powered (via an electric, hydraulic or pneumatic motor) to wind and unwind cables automatically. These reels provide efficient deployment and retrieval of long, heavy or mobile power and control cables. They are crucial for applications where cable handling must be safe, reliable and continuous.

Key Long-Tail Applications and Their Relevance

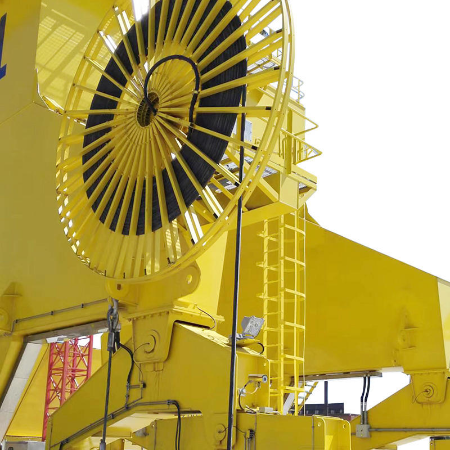

Application in Crane & Gantry Systems

In large crane and gantry installations, a motor cable reel for crane system ensures cable supply keeps pace with trolley movement, preventing sagging or damage. It allows long travel distances with constant tension control.

Key features:

- Automated winding/unwinding synchronized with crane motion.

- Slip-ring or contact system for continuous power/data transmission.

- Designed for heavy-duty cycle and dynamic load handling.

Heavy-Duty Industrial Reeling

A heavy duty motor driven cable reel industrial application covers mining, steel mills or manufacturing plants where cables must withstand high weights, long pay-out lengths and harsh conditions.

Key features:

- Robust drum materials (steel, special alloy) and large flange diameters.

- High motor torque, heavy duty bearings and frequent cycle capability.

- Corrosion protection and maintenance accessibility.

Shore-Power and Marine Winch Use

The use of a motorised cable reel for shore-power winch is typical in port or marine environments: here the reel handles shore power cables descending from quay cranes or vessels, where reliability and environmental protection are essential.

Key features:

- Compliance with marine-grade protections (IP55 or higher, salt spray resistance).

- Ability to wind/unwind over long distances while vessel or equipment is moving.

- Crash-stop, overload protection and proper grounding.

Low-Voltage Winding Devices

For less demanding environments, a low voltage motor cable reel winding device is used to manage power or signal cables in auxiliary equipment, e.g., workshops or automated lines. Although smaller in scale, specification and reliability remain key.

Key features:

- Rated for low voltage (e.g., ≤ 1000 V) and moderate cable lengths.

- Smaller footprint, simpler drive system and often lower cost.

- Still requires proper tensioning, cable protection and safe housing.

Custom Manufacturing / China Sourcing

When users look for a custom motor cable reel manufacturing China solution, they seek a tailored design—a specific drum size, drive system, mounting format, or certificate compliance. That’s where a supplier with strong design and production capacity comes in.

Key features:

- Tailored design: flange diameter, drum width, cable length, drive type.

- Manufacturing capacity to adapt: rapid tooling, local supply chain, export readiness.

- Quality standards compliance, e.g., ISO9001, national standards, testing equipment.

How to Choose a Motor Cable Reel – Selection Criteria

Selecting the right motor cable reel involves comparing various specifications and features. Below is a comparison table of different types and their suitable applications:

| Reel Type | Strengths | Best Application |

|---|---|---|

| Crane-system motor reel | Long travel, high dynamic tension, slip rings | Port gantries, overhead cranes |

| Heavy-duty industrial motor reel | Large cable capacity, rugged build | Mining, steel mill, heavy machinery |

| Shore-power motorised reel | Marine grade, long span, environmental protection | Docks, vessel power supply |

| Low-voltage winding device | Compact, cost-effective, moderate cycle | Workshops, auxiliary lines |

| Custom manufactured reel | Fully tailored design, export friendly | Special projects, OEM requirements |

Here are key factors to evaluate:

- Mechanical & electrical specifications: flange diameter, drum width, max cable length, motor torque, slip-ring rating.

- Drive system options: manual, motor-driven, hydraulic, variable frequency drive (VFD). Motor-driven reels are ideal for high cycle and automation. :contentReference[oaicite:1]{index=1}

- Duty cycle, environment & safety: frequent movement, outdoor/indoor, corrosive or marine conditions, IP rating, overload protection. :contentReference[oaicite:2]{index=2}

- Manufacturing & supply reliability: ability to deliver volume, technical documentation, certifications, local support.

Manufacturing & Supplier Insight

Let’s take the example of Jiangyin Kaida Mechanical and Electrical Manufacturing Co., Ltd., located in Yunting Industrial Zone, Jiangyin City—“the end of the river and the head of the sea”. The company’s factory covers 25,000 m², manufacturing area 12,500 m². After many years of production practice, the company has developed rapidly and its products cover all parts of the country.

Key manufacturing data:

- Annual capacity: shore power cable winches 1,000 units; low-voltage electrical appliances 10,000 units; lifting electromagnets 300 sets; winding devices 500 sets.

- Passed ISO9001 quality system certification; professional design & development team; advanced production technology; complete technical info and testing equipment; meets relevant national standards.

- More than 20 years’ experience in development and manufacturing of vertical and horizontal cable drums and shore power cable winches; one of the earliest manufacturers specialising in cable drums in China.

- Uses different drive systems according to different applications and specifications: includes plane scroll springs, weight type, hydraulic friction type, hysteresis clutch, variable torque and variable frequency control.

This illustrates their capability to deliver custom motor cable reels tailored to diverse requirements, aligning with the earlier discussion of “custom motor cable reel manufacturing China”.

Maintenance, Safety & Best Practices

Proper maintenance of a motor cable reel significantly extends service life and avoids downtime. Important practices include:

- Regular inspection of drum, bearings, drive system, slip rings and cable path.

- Cleaning and lubrication of moving parts according to manufacturer’s schedule.

- Avoiding cable over-stress: ensure payout & retrieval speeds are within spec, excessive bend radii are avoided. :contentReference[oaicite:3]{index=3}

- Store reels in protected environments if not used; prevent corrosion or moisture ingress especially in marine or outdoor applications.

- Ensure safety features (brakes, overload protection, emergency stop) are functioning, especially when used in moving equipment contexts.

The motor cable reel is a vital element in modern cable management for industrial, marine, crane, manufacturing and custom applications. By understanding specific use-cases such as motor cable reel for crane system, heavy duty motor driven cable reel industrial, motorised cable reel for shore-power winch, low voltage motor cable reel winding device, and custom motor cable reel manufacturing China, you can make informed choices in specification, procurement and maintenance.

Partnering with an experienced manufacturer like Jiangyin Kaida offers assurance of capacity, quality and tailor-made solutions. Investing in the right reel now means improved reliability, safety and lifecycle performance for your cable systems.

FAQ

- Q1: What load capacities should I check when choosing a motor cable reel?

A1: You should check maximum cable length, drum flange diameter, motor torque, duty cycle and environmental conditions. - Q2: Can I retrofit a motor cable reel into an existing crane system?

A2: Yes — many systems allow retrofitting; ensure the reel’s travel, mounting and slip-ring specs match the existing system. - Q3: How often should maintenance be performed on a motor cable reel?

A3: At least annually for typical use; in heavy-cycle or harsh environments, quarterly checks are advisable. - Q4: What differences exist between a reel for low-voltage winding device and heavy-duty industrial reel?

A4: The low-voltage device is smaller, handles shorter lengths and lower stresses; the heavy-duty reel supports longer lengths, heavier cables, harsher environments and higher duty cycles. - Q5: Why consider sourcing from China for custom motor cable reels?

A5: Chinese manufacturers like Jiangyin Kaida have strong production capacity, cost-efficiency, ability to tailor design, and mature quality systems (e.g., ISO9001) which can be beneficial for custom specifications.

русский

русский