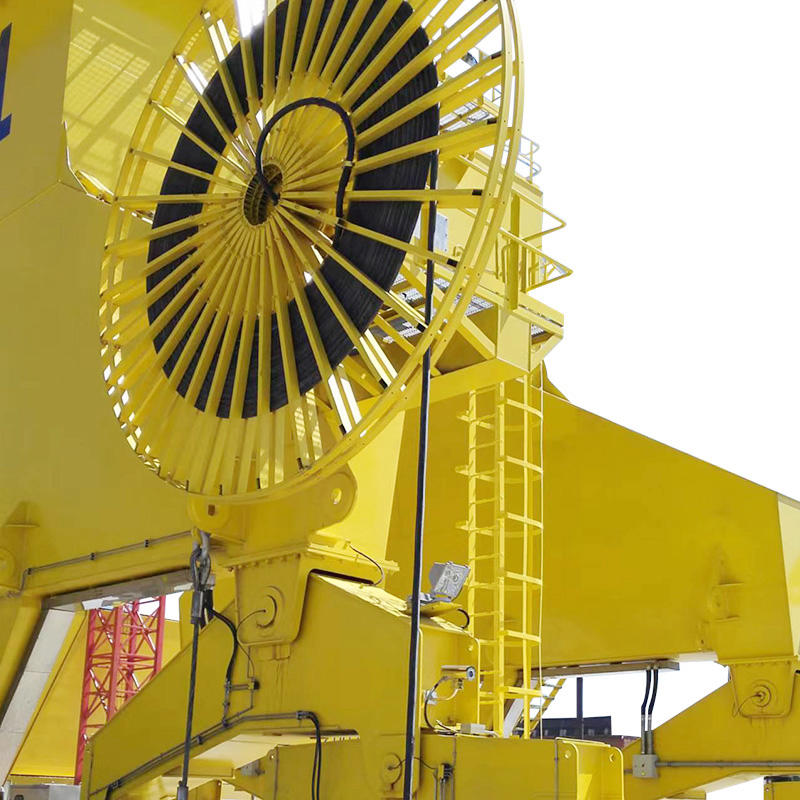

Understanding Motor-Driven Cable Reels

The seamless and safe operation of cranes and other heavy-duty machinery is fundamentally dependent on a reliable power and data supply. This is where motor-driven cable reels come into play, serving as a critical component in industrial automation and material handling. Unlike spring-driven or hand-cranked reels, motor-driven cable reels utilize an electric motor to actively wind and unwind the cable. This provides precise control over cable tension, which is paramount for managing heavy-gauge power cables or complex hybrid cables that combine power, control, and data lines. The core function of these reels is to ensure a continuous and protected supply of electricity and signals to moving equipment, while preventing a range of hazardous and costly issues such as cable entanglement, excessive slack, snapping, and premature wear. Selecting the appropriate reel is not merely a matter of convenience; it is a crucial decision that impacts operational safety, productivity, and long-term maintenance costs. For professionals tasked with specifying components for demanding environments, understanding the nuances of motor-driven cable reels is the first step toward optimizing the entire system's performance and reliability.

Key Factors in Selecting a Motor-Driven Cable Reel

Choosing the ideal motor-driven cable reel requires a thorough analysis of several interconnected factors. A misstep in any one of these areas can lead to subpar performance, frequent breakdowns, or even safety incidents. The selection process should be methodical, starting with a clear understanding of the application's specific demands and moving through a detailed assessment of the reel's technical specifications. The following sections break down these critical considerations to guide you toward an informed decision that ensures durability, efficiency, and safety for your heavy-duty applications.

Assessing Your Application's Requirements

Before delving into product specifications, a comprehensive assessment of the operational environment and the machinery's needs is essential. This foundational step dictates all subsequent choices.

Crane Type and Duty Cycle

The type of crane—be it an overhead bridge crane, a gantry crane, or a port container crane—directly influences the cable reel's operational demands. Furthermore, the duty cycle, which describes how frequently and intensively the crane operates, is a primary determinant. A crane operating in a steel mill with near-continuous usage has vastly different requirements compared to one used intermittently in a warehouse. The reel must be robust enough to handle the constant winding and unwinding without overheating or suffering from motor burnout. For high-duty cycle applications, reels with thermally protected motors and high ingress protection ratings are non-negotiable. The travel length of the crane also determines the amount of cable capacity needed on the reel.

Environmental Conditions

Industrial environments can be harsh, and the cable reel must be built to withstand them. Key environmental factors include:

- Temperature Extremes: Both high and low temperatures can affect the performance of the reel's motor, electrical components, and the cable itself.

- Exposure to Moisture and Corrosives: In environments like ports, chemical plants, or food processing facilities, reels require high IP (Ingress Protection) ratings (e.g., IP65, IP66, or higher) to resist water, dust, and corrosive substances.

- Presence of Explosive Atmospheres: In areas where combustible dust or gases may be present, reels must be certified for use in such hazardous locations (e.g., ATEX, IECEx).

- Mechanical Impact: The reel should have a sturdy construction to withstand potential physical impacts in a busy industrial setting.

Technical Specifications to Scrutinize

Once the application parameters are defined, the next step is to evaluate the technical specifications of the motor-driven cable reel. This is where the theoretical requirements meet practical product capabilities.

Cable Capacity and Dimensions

The reel must be physically compatible with the cable it is intended to carry. This involves more than just length. You must consider the cable's outer diameter, weight, and minimum bending radius. Overloading a reel with a cable that is too heavy or thick can strain the motor and lead to failure. Conversely, a reel that is too large for a thin cable can cause improper winding and guide issues. Manufacturers provide detailed charts specifying the cable capacity for their reels, which should be consulted meticulously. It is also crucial to account for any future upgrades that might involve different cables.

Motor Power and Torque Characteristics

The heart of the system is the electric motor. Its power and torque output must be perfectly matched to the cable's weight and the required tension. Insufficient torque will result in loose cable and poor retraction, while excessive torque can place undue stress on the cable, leading to deformation and damage to its internal conductors. The motor should provide smooth and consistent torque throughout the entire winding process. Furthermore, the motor's voltage and phase (e.g., 240V AC single-phase, 480V AC three-phase) must be compatible with the site's electrical supply. This careful matching is a core principle behind ensuring smooth cable winding for motor-driven reels, which is essential for maximizing cable service life.

Tension Control Mechanisms

Precise tension control is what sets motor-driven reels apart. The mechanism for controlling this tension can vary. Some reels use a simple mechanical torque limiter, while more advanced models feature electronic torque control that can be finely adjusted. This allows for optimal tension settings for different operational phases, such as a slightly higher tension during winding to ensure a tight and even cable wrap. Proper tension control prevents the cable from dragging on the ground, snagging, or becoming entangled with other equipment, thereby enhancing both safety and operational reliability.

Deep Dive into Core Selection Criteria

Beyond the initial factors, several core criteria demand a more detailed exploration. These elements are often the differentiators between a standard reel and one that delivers exceptional long-term value and performance in the most demanding scenarios.

Ensuring Durability in Harsh Environments

Durability is not a single feature but the result of a combination of design choices and material selections. For a motor-driven cable reel to survive in harsh industrial environments, several aspects must be prioritized. The reel's frame should be constructed from heavy-gauge steel or corrosion-resistant aluminum. All components, including bearings, slip rings, and guides, should be designed for a long service life with minimal maintenance. The surface finish, such as a powder-coated or galvanized treatment, provides an additional layer of protection against rust and chemical attack. The sealing system is particularly critical; high-quality lip seals and gaskets are necessary to achieve a high IP rating, effectively keeping out contaminants. When these elements are combined, they create a product capable of withstanding the rigors of daily industrial use, which is a fundamental aspect of finding a durable motor-driven cable reel for harsh industrial use.

Comparing Spring-Driven vs. Motor-Driven Reels

While motor-driven reels are the focus for heavy-duty applications, it is important to understand why they are often chosen over their spring-driven counterparts. The choice between the two technologies hinges on the application's demands for cable weight, length, and required tension control. The following comparison outlines the key differences.

Spring-driven reels utilize a pre-tensioned spring to provide the retraction force. While cost-effective for lighter loads, their torque decreases as the cable is unwound, which can lead to inconsistent tension. Motor-driven reels, on the other hand, use an electric motor to provide a consistent and controllable torque output regardless of the cable's position on the drum. This makes them vastly superior for heavy cables and long travel lengths. The table below provides a clearer comparison:

| Feature | Spring-Driven Reel | Motor-Driven Reel |

|---|---|---|

| Torque Output | Decreases as cable unwinds; inconsistent. | Consistent and controllable throughout the entire cycle. |

| Ideal Cable Weight | Light to medium weight. | Medium to very heavy weight. |

| Maximum Cable Length | Limited, typically shorter lengths. | Can accommodate very long cable lengths. |

| Tension Control | Basic, often not adjustable. | Precise and often electronically adjustable. |

| Initial Cost | Generally lower. | Higher initial investment. |

| Long-Term Reliability for Heavy-Duty Use | Lower; springs can fatigue over time. | Higher; designed for continuous, demanding operation. |

As the table illustrates, for cranes and heavy-duty applications where cable weight is significant and consistent tension is critical, motor-driven reels are the unequivocal choice.

Specialized Considerations for Complex Systems

Modern industrial machinery often requires more than just a power connection. The integration of data and control signals alongside power delivery introduces another layer of complexity that the cable reel must manage effectively.

Integrating Power, Control, and Data Cables

Many contemporary cranes and automated systems rely on hybrid cable systems that combine power conductors with fiber optics or data/control wires for communication, feedback, and control signals. Using a single, unified reel for such a hybrid cable is often more efficient and less prone to issues than using separate reels. This approach, however, requires a reel system designed to handle the specific challenges of hybrid cables. The reel must provide smooth winding to prevent sharp bends that could damage fragile fiber optic strands. Furthermore, the slip ring assembly—the component that transfers electrical signals from the stationary source to the rotating drum—must be of high quality. It needs to accommodate not only power circuits but also low-voltage data signals without causing interference or signal degradation. This is a critical factor for motor-driven reels for hybrid power and data cables, ensuring that both operational power and vital communication signals remain uninterrupted and clear.

Safety Features and Compliance Standards

Safety is paramount in any industrial setting, and cable reels contribute to a safe working environment in several ways. Key safety features to look for include:

- Automatic Shut-off: Limit switches that automatically stop the reel motor at the fully wound and fully unwound positions to prevent over-travel and potential cable damage.

- Emergency Stop Capability: Integration into the machine's emergency stop circuit.

- Thermal Protection: Built-in motor protection to prevent overheating during continuous or stalled operation.

- Robust Grounding: Proper grounding of the reel frame and through the slip rings to protect against electrical faults.

Compliance with international and regional safety standards is not optional. Look for reels that are designed and certified to meet standards such as IEC, UL, or CE. These certifications provide assurance that the product has been tested and meets specific safety requirements. Adherence to these standards is a fundamental component of safety standards for crane cable reels, helping to mitigate risks and ensure a safe workplace.

Optimizing Performance and Longevity

The final step after selection is to ensure that the motor-driven cable reel delivers on its promise over its entire operational lifespan. This involves proper installation, a consistent maintenance regimen, and a proactive approach to troubleshooting.

Installation and Maintenance Best Practices

Even the best reel will underperform if installed incorrectly. Installation should always follow the manufacturer's guidelines precisely. This includes correct mounting orientation, proper alignment with the cable guide system, and secure electrical connections. The foundation or mounting structure must be rigid enough to handle the forces exerted by the reel during operation. Once operational, a proactive maintenance schedule is essential. This includes:

- Regular visual inspections for signs of wear, damage, or corrosion.

- Checking and tightening all mechanical fasteners.

- Lubricating bearings and other moving parts as specified by the manufacturer.

- Inspecting the slip rings and brushes for wear and cleaning them to maintain good electrical contact.

- Verifying that the tension settings remain correct and adjusting if necessary.

A well-executed installation and consistent maintenance are the most effective strategies for maintenance tips for motor-driven cable reel systems, directly contributing to reduced downtime and a longer service life for both the reel and the expensive cable it carries.

Troubleshooting Common Issues

Despite best efforts, issues can arise. Being able to quickly identify and resolve common problems is key to minimizing operational disruption. Some typical issues include:

- Uneven Cable Winding: Often caused by misaligned cable guides, worn guides, or incorrect tension settings.

- Motor Failing to Operate: Can be due to a tripped thermal protector, a blown fuse, faulty limit switch, or a power supply issue.

- Excessive Noise: May indicate worn bearings, lack of lubrication, or a loose component.

- Erratic Tension: Could be a sign of a failing motor or a problem with the tension control system.

A systematic approach to troubleshooting, starting with the simplest solutions like checking power and fuses before moving to more complex components, is always recommended. Keeping a log of maintenance and any issues can also help in identifying recurring problems.

Selecting the right motor-driven cable reel is a complex but critical process that pays dividends in safety, reliability, and total cost of ownership. By methodically evaluating your application's needs, understanding the technical specifications, and committing to proper maintenance, you can ensure that your cranes and heavy-duty machinery have a robust and dependable cable supply system for years to come.

русский

русский