In the world of industrial automation, material handling, and heavy machinery, the efficient and safe management of power, control, and data cables is paramount. At the heart of this critical function lies the motor-driven cable reel. Unlike simpler spring or manual reels, motor-driven systems offer precise, automated control for the most demanding applications. This comprehensive guide delves into the technology, benefits, and selection criteria for motor-driven cable reels, providing the in-depth information needed to make an informed decision for your operations.

What is a Motor-Driven Cable Reel?

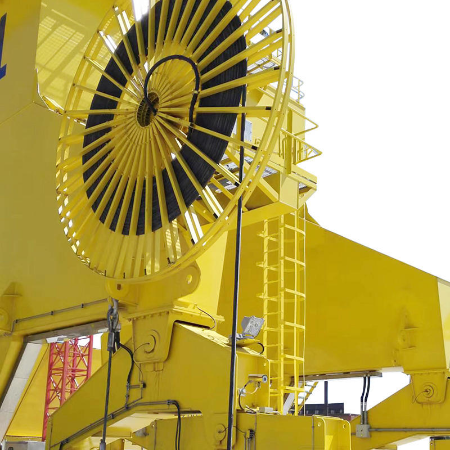

A motor-driven cable reel is a sophisticated electromechanical device designed to automatically wind and unwind cables or hoses using an electric motor as its primary power source. These systems incorporate a control mechanism—often a frequency inverter or a torque motor—that synchronizes the reeling motion with the movement of the connected machinery, such as a crane, hoist, or automated guided vehicle (AGV). This ensures the cable is maintained at a consistent tension, preventing damage from dragging, over-tensioning, or creating hazardous loops.

Jiangyin Kaida Mechanical and Electrical Manufacturing Co., Ltd., with over 20 years of specialization in cable reel systems, has been at the forefront of developing advanced motor-driven solutions. Our experience in designing motor-driven cable reels for automated guided vehicles (AGVs) and other high-tech applications ensures our products meet the rigorous demands of modern automation.

Key Advantages of Motor-Driven Systems

Choosing a motor-driven system over other types offers significant operational benefits:

- Precise Control: The motor allows for exact speed and torque management, enabling synchronized movement with the host machine.

- High Capacity: Capable of handling very long, heavy, and complex cable bundles, including those for power, data, and fluid transfer.

- Reduced Maintenance: Automated operation minimizes manual intervention and wear on cables, extending the lifespan of the entire system.

- Enhanced Safety: Eliminates tripping hazards from loose cables and protects cables from damage due to improper handling.

- Versatility: Suitable for both indoor and harsh outdoor environments, including marine and port applications.

Types of Motor-Driven Cable Reels

Different applications require different drive and control technologies. Here are the primary types:

1. Frequency Inverter Controlled Reels

These are among the most common and versatile types. The motor's speed is precisely regulated by a frequency inverter, which adjusts the electrical input to match the cable payout/rewind speed with the moving machinery's velocity.

- Ideal for: Cranes, hoists, stackers, and applications requiring variable speed and smooth acceleration/deceleration.

- Key Feature: Excellent synchronization, energy efficiency, and programmable control profiles.

2. Torque Motor Reels

This type uses a specially designed motor that provides a constant tension or torque output across its entire speed range.

- Ideal for: Applications requiring constant cable tension, such as in winding machines, or for handling delicate fiber optic or data cables.

- Key Feature: Delivers smooth, contactless torque without the need for additional slip rings in the torque transmission path.

3. Hydraulic Motor Driven Reels

Powered by hydraulic systems, these reels are known for their exceptional power density and robustness in extreme conditions.

- Ideal for: Heavy-duty mining equipment, marine deck machinery (like marine and offshore motor-driven cable reels), and environments with explosive risks where electric sparks are a concern.

- Key Feature: High torque at low speeds, inherent explosion-proof capability, and reliable performance in dirty or wet environments.

Comparison of Motor-Driven Reel Types

The following table provides a clear comparison to help identify the best-suited technology for specific needs.

| Type | Best For | Control Precision | Environment | Typical Applications |

| Frequency Inverter Controlled | Variable speed, synchronized motion | Very High | General industrial to harsh | Overhead cranes, automated storage systems |

| Torque Motor | Constant tension applications | High | Clean to moderate industrial | Fiber optic winding, material testing machines |

| Hydraulic Motor | Extreme duty, high torque, hazardous areas | Moderate | Very harsh, explosive, marine | Mining shovels, offshore winches, ship-to-shore power |

Core Applications and Industry Solutions

Motor-driven reels solve critical challenges across diverse sectors by providing reliable cable management.

Industrial Automation and Material Handling

- Overhead Cranes and Gantries: Essential for delivering power and control to moving crane trolleys and hoists over long distances.

- Automated Guided Vehicles (AGVs): Custom-designed motor-driven cable reels for automated guided vehicles (AGVs) ensure continuous power and data communication without restricting movement, a key to 24/7 warehouse and factory automation.

Port and Maritime Operations

- Shore Power Cable Winches: A core specialty of Jiangyin Kaida, these motor-driven winches are crucial for connecting vessels at berth to land-based electrical grids, reducing emissions and engine noise. They must withstand corrosive saltwater environments.

- Shipboard Deck Machinery: Used for handling communication, power, and hose lines during loading, unloading, and towing operations.

Specialized and Heavy Industries

- Mining and Tunneling: Hydraulic motor-driven reels power drills, cutters, and ventilation systems on continuous miners and tunnel boring machines in rugged, dusty conditions.

- Stage and Entertainment: Precisely control the movement of lighting, sound, and special effects cables for dynamic performances.

How to Select the Right Motor-Driven Cable Reel

Selecting the appropriate reel requires a detailed analysis of your application's parameters. A thorough assessment is crucial, as highlighted in industry best practices for industrial cable management[1].

Step 1: Define Technical Specifications

- Cable/Hose Data: Outer diameter, weight per meter, minimum bending radius, and number of cores/media.

- Travel Length: The maximum required payout distance.

- Speed & Acceleration: Maximum linear speed of the moving point and desired acceleration profile.

- Environmental Conditions: Temperature range, presence of dust, moisture, chemicals, or explosive atmospheres (requiring certifications like ATEX).

Step 2: Choose the Drive and Control System

Based on the specs from Step 1, decide between frequency inverter, torque motor, or hydraulic drive. Consider the required control feedback (e.g., encoder signals for synchronization) and the power supply available (AC voltage, hydraulic pressure). For applications like low maintenance motor-driven cable reels for industrial cranes, a robust and well-sealed frequency inverter system is often the optimal choice for longevity.

Step 3: Consider Structural and Safety Features

- Frame Construction: Steel or stainless steel for corrosion resistance, especially for marine and offshore motor-driven cable reels.

- Cable Guidance: Include a level-wind system for multi-layer winding to ensure neat, even spooling.

- Safety Devices: Limit switches for end-of-travel, slip rings for uninterrupted transmission, and emergency stop functions.

For specialized needs, such as a customizable motor-driven cable reel system for heavy machinery, partnering with an experienced manufacturer like Jiangyin Kaida is vital. Our team can engineer solutions that integrate seamlessly with your specific machine's operational profile.

Step 4: Prioritize Reliability and Support

Evaluate the manufacturer's expertise, quality certifications (like ISO9001, held by Jiangyin Kaida), and ability to provide spare parts and technical support. A reliable motor-driven cable reel is a long-term investment in operational uptime.

Installation, Maintenance, and Troubleshooting Tips

Proper installation and care maximize the service life of your reel system.

Installation Best Practices

- Mount the reel on a stable, aligned structure to prevent undue stress.

- Ensure proper electrical grounding and follow all wiring diagrams.

- Correctly thread the cable through guides and tensioners as per the manual.

Routine Maintenance Checklist

- Visual Inspection: Regularly check for cable jacket wear, damaged guides, or loose hardware.

- Bearing and Slip Ring Service: Lubricate bearings as scheduled and inspect slip rings/brushes for wear to maintain electrical continuity[2].

- Drive System Check: Inspect motor connections and, for hydraulic systems, check fluid levels and hose integrity.

Common Issues and Solutions

| Problem | Possible Cause | Solution |

| Uneven Cable Winding | Misaligned level-wind mechanism or incorrect cable entry angle | Realign level-wind guide and check mounting |

| Motor Overheating | Excessive load, incorrect voltage, or blocked ventilation | Verify load capacity, check power supply, clear vents |

| Erratic Tension | Faulty torque setting, sensor issue, or mechanical binding | Recalibrate control parameters, inspect sensors and guides |

Why Partner with a Specialist Manufacturer?

The design and manufacturing of a reliable motor-driven cable reel require deep engineering knowledge and practical experience. Jiangyin Kaida Mechanical and Electrical Manufacturing Co., Ltd., strategically located in Jiangyin City with its excellent logistics network, is recognized as one of China's earliest specialists in cable reel production. With a 25,000 sqm facility and a dedicated R&D team, we possess the expertise to develop solutions ranging from standard shore power winches to highly customizable motor-driven cable reel systems for heavy machinery.

Our philosophy of "honesty, down-to-earth, high-quality service, and sustainable development" drives us to provide not just products, but reliable partnerships. We understand that a low maintenance motor-driven cable reels for industrial cranes can significantly reduce total cost of ownership, which is why our designs emphasize durability and serviceability.

Frequently Asked Questions (FAQs)

1. What is the main difference between a motor-driven reel and a spring-driven reel?

Spring-driven reels rely on the mechanical energy of a wound spring to rewind the cable and are best for lighter loads and shorter lengths. Motor-driven cable reels use an electric or hydraulic motor for both winding and unwinding, offering active, precise control, much higher force capacity, and synchronization with moving equipment, making them suitable for heavy-duty, automated applications.

2. Can motor-driven reels handle combined power and data cables?

Yes, absolutely. They are ideally suited for this purpose. They can be designed with separate channels or a central drum to manage hybrid cables or multiple separate cables simultaneously, ensuring synchronized payout/rewind for all media—a common requirement in motor-driven cable reels for automated guided vehicles (AGVs).

3. How do I protect a motor-driven reel in a harsh outdoor or marine environment?

Specify corrosion-resistant materials like galvanized or stainless steel enclosures. Ensure the motor and electrical components have appropriate ingress protection (IP) ratings (e.g., IP65 or higher). For the most demanding marine and offshore motor-driven cable reels, additional coatings, sealed bearings, and anti-corrosive treatments are applied to withstand salt spray, humidity, and temperature fluctuations.

4. What factors most influence the cost of a motor-driven cable reel system?

The primary cost drivers are the required cable capacity (length, diameter, weight), the type and power of the drive motor, the sophistication of the control system (e.g., standard vs. programmable inverter), the construction materials (standard steel vs. stainless), and any custom engineering required for integration.

5. How long does a typical motor-driven cable reel last?

With proper selection, installation, and maintenance, a high-quality motor-driven reel system can last for 10 to 20 years or more. The lifespan heavily depends on the operating environment, duty cycle, and adherence to maintenance schedules. Choosing a low maintenance motor-driven cable reels for industrial cranes from a reputable manufacturer is key to achieving maximum longevity and return on investment.

References

[1] Smith, J., & Davis, R. (2020). *Best Practices in Industrial Cable and Hose Management*. Engineering Systems Press. (Guidelines on systematic assessment for cable management system selection).

[2] "Maintenance of Rotating Electrical Contacts in Harsh Environments." (2019). *Journal of Electrical Maintenance and Reliability*, 12(3), 45-52. (Information on servicing slip rings and brushes).

русский

русский