In the world of modern industrial operations, efficient and reliable management of cables and hoses is paramount. This is where motor-driven cable reels come into play, serving as a critical component that ensures the seamless supply of power and data to mobile machinery. Unlike their manual counterparts, these automated systems provide consistent tension, prevent damage from kinks and tangles, and dramatically enhance operational safety and efficiency. This article serves as an in-depth guide, exploring various types of motorized reels to help you select the best fit for your specific application, whether you require a custom solution, a heavy-duty workhorse, or a specialized unit for a crane or fluid transfer system. By understanding the unique features and benefits of each type, you can make an informed decision that improves productivity and extends equipment lifespan.

A motor-driven cable reel is a mechanized device designed to automatically pay out and retract flexible cables, hoses, or similar conduits. Its core function is to maintain a constant, controlled tension on the cable, preventing it from being stretched too tightly or becoming too loose. This continuous tension is essential in dynamic applications where machinery moves over long distances, such as in ports, mining operations, or automation systems. The motor, often controlled by an integrated drive system, works in perfect synchronization with the equipment's movement, ensuring the cable is always managed properly. The benefits of this technology are vast, including reduced manual labor, enhanced safety by eliminating tripping hazards, and significantly increased operational uptime by preventing cable wear and tear. As you'll discover in the following sections, the capabilities of these reels extend far beyond simple power delivery, offering specialized solutions for a wide range of challenging industrial environments.

Meeting Unique Needs with Custom Solutions

Custom motor-driven cable reels: A Tailored Approach

In many industries, a standard, off-the-shelf cable reel simply won’t suffice. This is where custom motor-driven cable reels become an indispensable solution, designed from the ground up to meet the precise and often complex demands of a unique application. The need for customization arises from a variety of factors, including extreme environmental conditions, specialized cable types, or non-standard operational requirements. For example, a reel destined for a high-temperature steel mill requires different materials and cooling systems compared to one used in a low-temperature food processing facility. Similarly, a reel managing sensitive fiber optic cables needs a different level of tension control and protection than one handling a heavy power cable.

The primary advantage of opting for a customized reel lies in its ability to deliver superior performance and reliability in challenging scenarios. Key aspects of a custom design include:

-

Material and Construction:

Choosing the right materials is critical for longevity. A custom reel can be constructed from marine-grade aluminum for saltwater environments, or from specialized alloys to resist corrosive chemicals. The enclosure can be designed to be dust-proof and waterproof (IP-rated) for outdoor use, or explosion-proof for hazardous areas. The structural frame can also be reinforced to withstand heavy vibrations or impact, ensuring the reel remains operational under intense stress.

-

Speed and Control Systems:

The winding speed of a reel must precisely match the speed of the machine it is servicing. A custom system can incorporate variable frequency drives (VFDs) and sophisticated control algorithms to ensure perfect synchronization. This is vital for applications like high-speed stacker cranes in automated warehouses, where any mismatch in speed could lead to dangerous cable slack or excessive tension. The control system can also be programmed with specific winding patterns to prevent uneven layering, which can lead to premature cable failure.

-

Drum Capacity and Size:

The physical dimensions of the reel, including the drum diameter and width, are often a constraint. Customization allows for the reel to be built to a specific footprint, maximizing space efficiency. This is particularly important on mobile vehicles or in confined spaces. The drum capacity can also be fine-tuned to accommodate a precise length and diameter of cable, optimizing weight and performance.

-

Integration with Existing Systems:

A bespoke reel can be engineered to seamlessly integrate with a facility’s existing PLC (Programmable Logic Controller) or SCADA (Supervisory Control and Data Acquisition) systems. This allows for real-time monitoring and control of the reel's status, including speed, position, and tension, as well as enabling predictive maintenance based on usage data. This level of integration is essential for modern, interconnected industrial operations that rely on data for efficiency and safety.

By investing in a custom solution, companies can resolve complex operational challenges, extend the life of expensive cables, and ensure uninterrupted power supply in the most demanding environments. This tailored approach moves beyond the limitations of standard products, providing a reel that is not just a component, but a perfectly engineered part of a larger, more efficient system.

Robust Solutions for Industrial Demands

Heavy-duty industrial cable reels with motor: The Workhorses of Industry

In the most demanding environments on Earth, standard equipment often fails. This is precisely the reason for the existence of heavy-duty industrial cable reels with motor. These are not merely powered spools; they are rugged, purpose-built systems designed to withstand the relentless abuse of mining, steel manufacturing, and port operations. The key to their durability lies in their construction and the materials used. Unlike lighter-duty models, these reels feature reinforced steel frames, robust gearboxes, and motors that can handle continuous, high-torque operation without overheating. Their components are selected to resist wear and tear from dust, grime, and physical impact, ensuring they can perform reliably in conditions that would quickly destroy less capable equipment.

The applications for these heavy-duty reels are as varied as they are challenging:

-

Mining and Quarrying:

In mining operations, excavators and draglines require massive power cables that can be several miles long. The constant movement, abrasive dust, and potential for rock falls necessitate a reel that is incredibly tough and reliable. A heavy-duty reel for this sector is designed with a sealed enclosure to keep out debris and a powerful motor to manage the immense weight of the cable, ensuring uninterrupted power to machines that are critical for production.

-

Steel Mills:

Steel manufacturing environments are characterized by extreme heat, corrosive fumes, and heavy vibrations. The cables supplying power to transfer cars and mobile machinery must be managed by a reel that can operate flawlessly in these conditions. Heavy-duty reels for steel mills are often equipped with insulated motors and specialized coatings to protect against heat and corrosion, ensuring the safety of workers and the continuity of the production line.

-

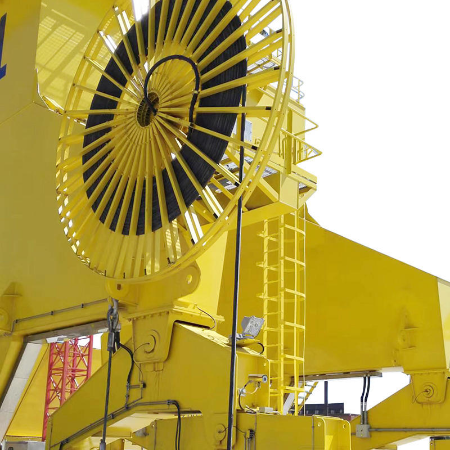

Port and Crane Operations:

At bustling ports, gantry cranes and ship-to-shore cranes are in constant motion. The cables powering these giants are subject to extreme tension and rapid acceleration and deceleration. Heavy-duty reels designed for ports are built to handle these dynamic loads and are often mounted on large, rotating platforms. They feature sophisticated braking systems and tension-control mechanisms to prevent cable damage and ensure the crane’s mobility is not compromised.

The technology inside these heavy-duty reels is just as robust as their exterior. They often include advanced tensioning systems that automatically adjust to the cable's load, preventing both slack and over-tensioning, which are common causes of cable failure. They may also be equipped with slip rings that can handle very high currents, as well as fiber optic and data rings for communication. In these environments, downtime is incredibly costly, and a heavy-duty reel is seen not as an expense, but as a long-term investment in operational reliability and safety. Their ability to consistently perform under extreme stress makes them a vital piece of the industrial puzzle, ensuring that even the most demanding jobs can be done without interruption.

The Crane's Essential Partner

Motorized cable reel for cranes: Ensuring Uninterrupted Mobility

Cranes, by their very nature, are designed for dynamic, multi-directional movement. Whether it’s a gantry crane traversing a massive warehouse or a ship-to-shore crane lifting containers at a port, their ability to move freely is essential. Powering these colossal machines requires a specialized solution: the motorized cable reel for cranes. This device is specifically engineered to manage the unique demands of a crane’s operational cycle, which involves frequent starting, stopping, and changes in direction. Unlike a simple winding machine, a crane reel must synchronize its speed and tension with the crane's movement to prevent the cable from dragging on the ground, getting tangled, or being subjected to damaging forces.

The design of a crane reel focuses on three core performance areas:

-

Tension Management:

Maintaining constant tension on the cable is the single most critical function. Too much tension can over-stress the cable, leading to conductor breakage, while too little tension can cause slack, creating a safety hazard and a high risk of the cable being crushed or snagged. Crane reels use sophisticated motor controls and counterweights to ensure the perfect amount of tension at all times, regardless of the crane’s speed or direction.

-

Controlled Pay-Out and Retraction:

A crane reel must be able to smoothly pay out the cable as the crane moves away from its power source and retract it just as smoothly as it returns. This requires a reliable motor and gearbox that can handle the constant acceleration and deceleration. The system is often integrated with the crane's PLC to ensure its speed is always a direct function of the crane’s travel, eliminating any risk of cable mismanagement.

-

Safety and Protection:

Safety is non-negotiable in crane operations. The reels are equipped with a variety of safety features, including limit switches to prevent over-travel, anti-slack sensors that stop the motor if the cable loses tension, and emergency stop buttons. These features not only protect the cable but, more importantly, prevent accidents involving workers or other equipment on the ground. Additionally, the cable itself is often a high-flex, reinforced type, designed to withstand the thousands of winding cycles it will endure over its lifetime, all managed by the reel.

In addition to power cables, many crane reels are designed to manage fiber optic and data cables simultaneously through specialized slip rings. This allows for continuous communication between the crane and its control center, enabling real-time diagnostics, remote operation, and data transfer. By ensuring that the crane's power and communication lines are always properly managed, these specialized reels significantly enhance operational efficiency, reduce the potential for costly downtime, and contribute to a safer working environment. They are, in essence, the lifeline of the crane, providing the constant, reliable connection needed to keep massive operations moving forward.

The Future of Cable Management

Automatic cable winding machine for large cables: Driving Efficiency Through Automation

In the past, managing large, heavy cables for industrial machinery required significant manual effort, leading to inefficiencies and safety risks. Today, the advent of automation has transformed this process. The automatic cable winding machine for large cables represents the pinnacle of this evolution, providing a solution that is not only more efficient but also far safer and more reliable. These machines are designed to autonomously manage the spooling and unwinding of substantial cables, from high-voltage power lines to multi-core control cables, without the need for constant human intervention. Their core function is to eliminate the variables of manual operation—like inconsistent tension and improper winding—that lead to premature cable wear and operational hazards.

The key features that define an automatic winding machine include:

-

Advanced Tensioning Systems:

Unlike simple spring-loaded or motorized reels, an automatic machine uses sensors and intelligent motor controls to continuously monitor and adjust cable tension. This ensures the cable is always taut enough to prevent slack but never so tight that it is over-stressed. This precise control extends the life of the cable by minimizing fatigue and wear on the conductors and sheathing.

-

Layering and Spooling:

One of the most common causes of cable damage is improper winding, which can lead to pinching or crushing of inner layers. An automatic winding machine incorporates a self-aligning system that guides the cable onto the drum in a perfectly uniform and non-overlapping pattern. This ensures that the cable is always spooled correctly, maximizing the life of the cable and the efficiency of the winding process.

-

Integrated Safety Features:

These machines are designed with a host of safety features to protect both the equipment and personnel. This includes emergency stop buttons, obstacle detection sensors that halt the winding process if an object is in the way, and automatic braking systems that prevent the reel from free-wheeling in the event of a power failure. The automation of the process also keeps workers away from the large, heavy moving parts, significantly reducing the risk of accidents.

-

Reduced Manual Labor and Downtime:

By automating the entire cable management process, these machines drastically reduce the amount of manual labor required. Operators can focus on other tasks, knowing that the cable is being managed safely and efficiently. Furthermore, the longevity and reliability of the cables managed by an automatic system lead to a significant reduction in unexpected downtime for repairs or replacements. This contributes directly to a more productive and profitable operation.

The future of industrial cable management is undoubtedly in automation. As industries move towards smart factories and interconnected systems, the role of an automatic cable winding machine for large cables will become even more critical. They are a fundamental building block of an efficient, safe, and modern industrial environment, ensuring that the vital flow of power and data remains secure and uninterrupted.

Beyond Cables: The Versatility of Motorized Reels

Motor-driven hose reels for fluid transfer: A Multi-Purpose Solution

While the primary application of motorized reels is often associated with electrical cables, their versatility extends to a wide range of other conduits, including hoses. The motor-driven hose reels for fluid transfer are a specialized category of equipment designed to manage the payment and retraction of hoses used for conveying liquids, gases, and other fluids. These reels are essential in industries where hoses are frequently used over large distances and must be handled carefully to prevent kinking, twisting, and damage to the hose material or connections. Their robust construction and automated control systems ensure that fluid transfer operations are carried out smoothly and safely, minimizing spills and maximizing efficiency.

Applications for these motorized hose reels are diverse and critical to various sectors:

-

Fuel and Lubricant Transfer:

In the aviation and marine industries, motorized hose reels are used for the safe and efficient transfer of fuel. The automated winding ensures that heavy, cumbersome hoses are managed with ease, reducing the physical strain on operators and minimizing the risk of leaks or spills. These reels often feature specialized seals and materials to prevent corrosion from the fluids they handle.

-

Agricultural and Fire Fighting:

In agriculture, these reels are used to manage irrigation hoses, while in fire fighting, they are vital for the rapid deployment and retraction of high-pressure water hoses. The automated nature of the reel allows for quick response times and safe operation, as a motor handles the significant weight and drag of a water-filled hose.

-

High-Pressure and Pneumatic Systems:

Industries that rely on high-pressure water or air for cleaning and other processes use these reels to manage their supply lines. The controlled retraction of the hose prevents it from whipping or causing injury, which is a major safety concern in high-pressure applications. The motorized reel ensures the hose is always stored in a safe, controlled manner, ready for the next use.

The benefits of using a motor-driven hose reel become even clearer when compared to traditional manual winding methods. While a manual reel might seem sufficient for smaller tasks, the risks and inefficiencies become apparent in large-scale operations. A manual reel requires significant physical effort, which can lead to operator fatigue and injury. Furthermore, it is difficult to maintain consistent tension, which can cause kinks and uneven spooling, shortening the hose’s life. A motorized system, by contrast, eliminates these risks. It provides a safer, more efficient, and more reliable way to manage fluid transfer hoses. The following table provides a clear comparison of the two methods:

Manual winding requires significant physical effort and can cause operator fatigue, leading to inconsistent winding and a higher risk of kinking and hose damage. This can shorten the lifespan of the hose and create safety hazards. In contrast, a motorized reel automates the process, ensuring consistent tension and uniform spooling. This preserves the integrity of the hose, extends its operational life, and significantly reduces the risk of injury to personnel, as they are not required to exert physical force on the hose. The motorized reel handles the strain, providing a safer and more efficient solution for large-scale fluid transfer operations.

| Feature | Manual Hose Reel | Motor-Driven Hose Reel |

|---|---|---|

| Effort Required | High physical effort, prone to fatigue | Minimal physical effort, automated |

| Tension Control | Inconsistent, depends on operator | Consistent and controlled automatically |

| Safety | Higher risk of injury from strain or whipping hose | Lower risk of injury, automated process |

| Hose Lifespan | Reduced due to kinking and uneven winding | Extended due to proper winding and tension |

русский

русский